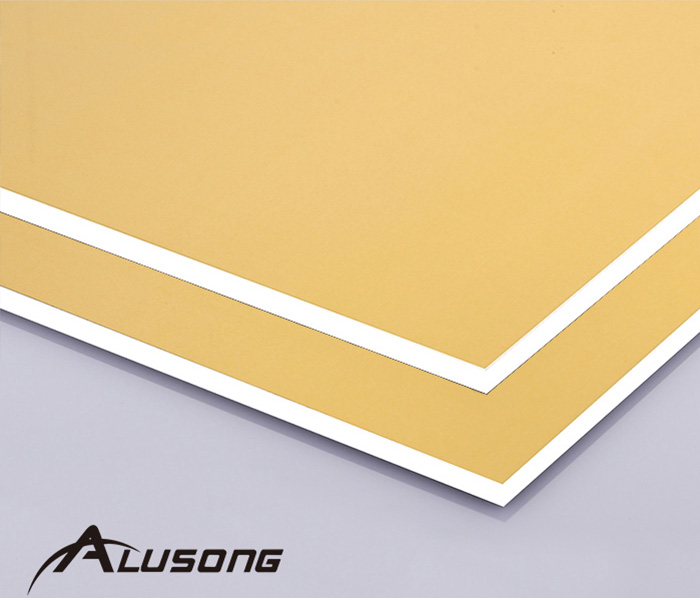

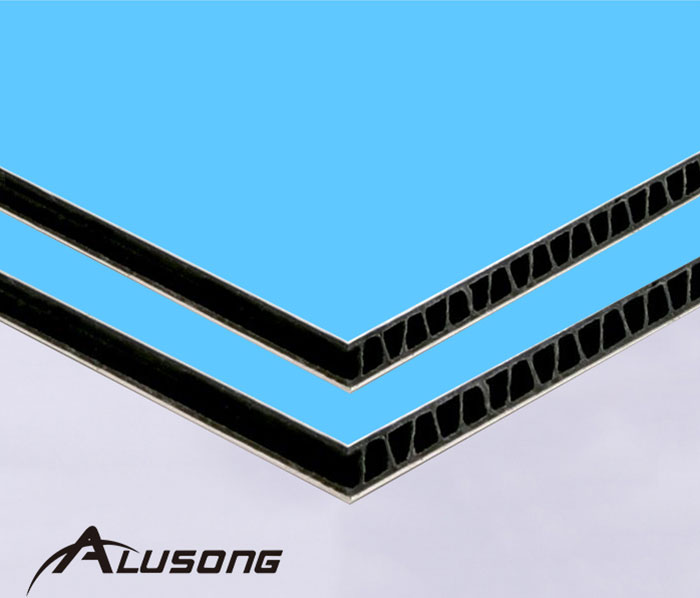

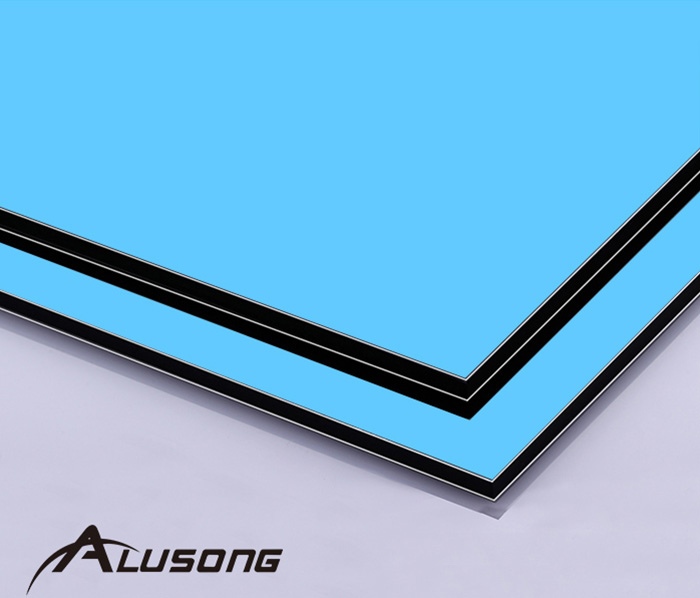

ALUSONG A2 core is a composite panel which sandwiched by two layers of aluminum coating skin and non-combustion core. The decorative layer is coated with high performance PVDF system which supplied form KANAR 500 or HYLAR 5000 70% PVDF resin authorized paint company to ensure an excellent exterior durability while offer the more selections. These coating are finished on continuous process coil coating line, which make the color and gloss uniform are better than other coating process available in market.

| Aluminum alloy | AA1100 AA3003 AA5005 |

| Aluminum skin | 0.21mm,0.30mm,0.35mm,0.40mm,0.45mm,0.5mm |

| Panel thickness | 3mm,4mm,5mm,6mm |

| Panel width | 1220mm,1250mm,1500mm |

| Panel length | 2440mm,3050mm,4050mm |

| Surface treatment | PE&PVDF |

| Colors | 70 colors, RAL & PANTONE colors upon request |

| Customers size | accepted |

| Glossy | 20%-80% |

Panel width: ±2mm Panel length:±3mm

Panel thickness: ±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.02mm

Raw material:

Base material: High strength aluminum alloy sheet

PE core material: Non-combustion mineral material A2 grade

Surface coating: PVDF, Polyester, FEVE, NANO -PVDF, Spectra

Back coating: Primer coating

Product Properties:

*Safe &Fire Resistant

ALUSONG Fire Resistant Aluminum Composite Panel reaches A2-s1, d0, t0 grade according to the national standard GB 8624-2006, with non-combustible inorganic core material, which will not get fire and then resist fire spread while a building gets fire.

*Environmentally Friendly

It meets the national standard on green and environment protection for construction materials with the characteristics of innocently, no halogen, no smoke, non combustible no poison, odorless, heat-and sound-insulating, etc

*Weather Resistant &Anti-pollution

Coated with PVDF which is composed of HYLR5000 or KYNAR5000.It is good anti-aing for oxygen and light-heat, Strong durability in high and low temperatures, waterproof and moisture proof.

1 Wall curtain, Cladding and Facade

2 Hotels and commercial mansions

3 Exterior renovation for old buildings

4 Subway and airports

5 Industry plants and materials,

6 Vehicle and boat materials

-

Application

-

Application

-

Application

-

Application

-

Application

-

Application

The contrast of fire-resist performance in different countries

Standard China Germany U.S.A France U.K Japan Russia

Burning Degree| GB/T8627 DIN 4102 ASTM E84 BS 476 NFF 16-101 JIS K6911 30244-94

Few A A1,A2 NC O M0 1 T1

----------------------------------------------------------------------------------------------------------------------

Minor B1 B1 A 1 M1,M2 2 T2

----------------------------------------------------------------------------------------------------------------------

Normal B2 B2 B,C 2,3 M3 3 T4

----------------------------------------------------------------------------------------------------------------------

Serious B3 B2 4 M4, M5 - -

The level and combustion properties of names

Degree Item Degree Item

A None-combustion B2 Combustion

------------------------------------------------------------------------------------------------------------------------------------------

B1 Hard-combustion B3 Combustion

-----------------------------------------------------------------------------------------------------------------------------------------

Degree Material The combustion performance indicators

-----------------------------------------------------------------------------------------------------------------------------------------

None-combustion Class A Material According to GB/t8625 test, the average length of the remaining

≤35cm(Including any residual specimen ≥20cm) for each

test and average flue gas temperature peak ≤150 ℃,no

Specimen back burner the scene; According to GB/8627 test,

Their smoke density levels (SDR) ≤ 15;

According to GB/T14002 and GB/T14403 test, its calorific

Value ≤16.8M/ ㎡

Toxicity materials combustion flu gas of the entire

non-lethal concentration of ≥ 25mg/L

----------------------------------------------------------------------------------------------------------------------

Hard-combustion Class B1 Material According to GB/T8626 test, its combustion properties should be

met GB/T8626,and does not allow any dropping of combustion

Burn the filter paper;

According to GB/8625 test, the average of each specimen

remaining length ≥ 15cm(Including any residual specimen

Length ≥0cm),and average peak temperature of gas ≤ 200℃

In each test

According to GB/8627 test, their smoke density level (SOR)≤75