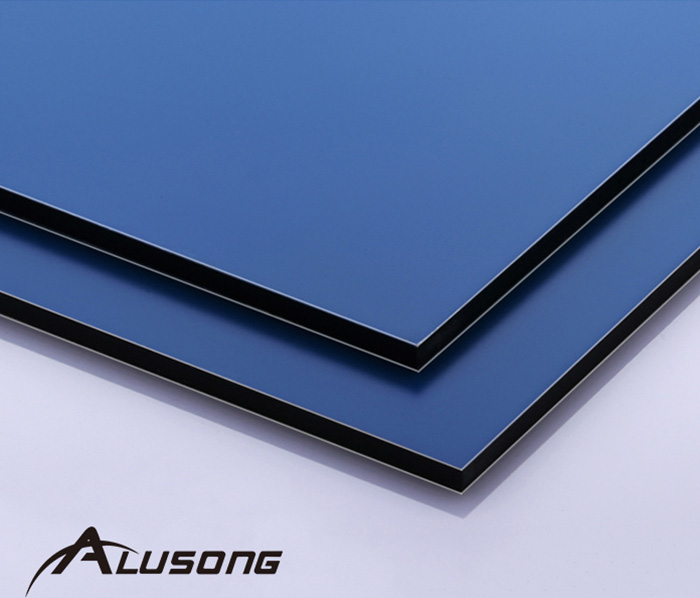

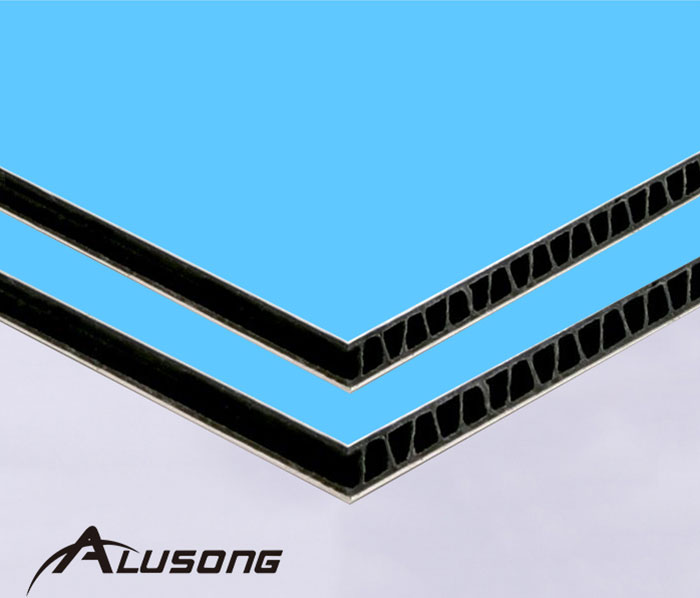

ALUSONG Polyester aluminum composite panel consists of aluminum layers on both sides with a polyethylene core. It’s coated with a polyester lacquer. The low weight sheet material can be easily fabricated, making it an ideal material for creative applications both indoors and outdoors.

| Aluminum alloy | AA1100 |

| Aluminum skin | 0.1mm,0.15mm,0.18mm,0.21mm,0.30mm,0.40mm,0.5mm |

| Panel thickness | 2mm,3mm,4mm,5mm,6mm |

| Panel width | 1220mm,1250mm,1500mm |

| Panel length | 2440mm,3050mm,4050mm |

| Surface treatment | Polyester |

| Colors | 80 colors, special colors available upon request |

| Customers size | accepted |

| GLOSSY | 20%-80% |

Panel width: ±2mm Panel length:±3mm

Panel thickness: ±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.01mm

Raw material:

Base material: high strength aluminum alloy sheet

PE core material: non-toxic low density polyethylene

Surface coating: polyester coating

Back coating: primer coating

Product properties

Lightweight, excellent printable surface

Outstanding color & glossy retention

Superior impact & peel strength

Excellent surface flatness & smoothness

Various color & easy to maintain

1. Interior Decoration

2. Roof edges and Parapet wall

3. Dado, Separation wall and Partition

4. , Ceiling, Bathroom, Kitchen and Balcony

5. Advertisement boards, display platforms and signboards

6. Column covers and Beam wraps

7. Industrial materials, vehicle and boat materials

| Description | Test standard | Polyester |

| Thickness of coating | Polyester paint≧16um | 16um to 18um |

| Coating flexibility (T-bend) | Polyester paint≥3T | 3T |

| Color different | ΔE≦2.0(follow color sample) | ΔE≦2.0 |

| Pencil hardness | ≧HB | ≧2H |

| Chemical resistance | 2%HCI or 2% NaOH test in 24 hours -No change | No change |

| Coating adhesion | ≧1grade for 10*10mm2 gridding test | 1grade |

| Resist solvent | 100times with Dimethy benzene without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average ≧5N/mm of 180oc peel off for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropprate ≦10% | Change of glossy only,no paint Peel off |

| Coefficient of linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition,glossiness deviation less grade 2,color difference ≦4.0 | No change |